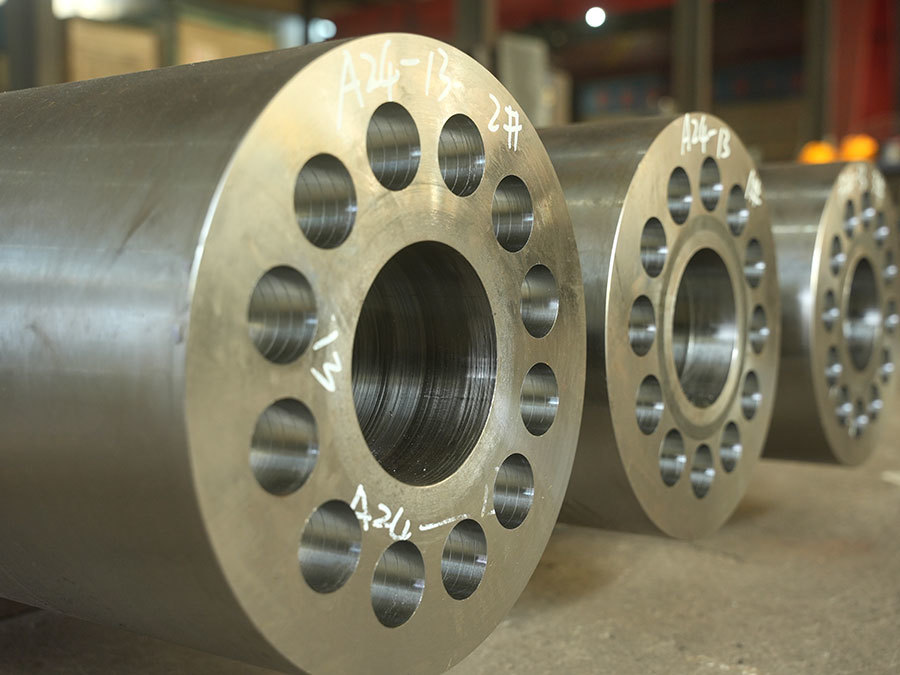

How is the flower roller made?

【Summary】Unloading: seamless steel pipe for roller body, 45# round steel for shaft head and flanges at both ends.

1. Unloading: seamless steel pipe for roller body, 45# round steel for shaft head and flanges at both ends.

2. Turning processing: turning the joint surface of the cooperation part of the roll body, end plate and the first part of the shaft.

3. Welding process: (According to the drawings, if there is a structure such as oil or water flow inside the roller body, the inner tube welding process should be carried out in advance) Roller inner tube welding: check the coaxiality of the two shafts and the inner sleeve, only welding The inner end plate on the shaft head. Put the inner sleeve into the roller body, and weld the cooperative junction between the inner end plate and the roller body. Install the outer end plate on the two shafts, and weld the junction of the outer end plate and the joint surface of the shaft and the roller body.

4. The roll blank is annealed.

5. One end of the steel roller shaft is flattened, and the standard center hole is drilled.

6. Turning processing: Divide rough and fine-turned steel roller body parts to the drawing requirements standard, then set the center frame, turn the end face, and drill to the standard.

7. Process the markings on the surface of the roller according to the requirements of the customer's markings. This is an important part of the embossing roll manufacturing process. The embossing roll manufacturing staff must have ample experience and formulate the production process according to the requirements of the customer's markings. In the production process, the embossers must be careful, and meticulous. The markings produced must be clear, rich in layers, and have a strong three-dimensional effect.

8. After the marking is completed, the surface of the roller is plated with a hard chrome layer or sprayed with other materials (depending on the purpose of the customer's embossing roller).

9. Check the static balance of the steel roll with the embossing machine.

Related Blog

The difference between composite roll and cemented carbide roll and its application characteristics?

The non-destructive testing of composite rolls is usually carried out with an ultrasonic flaw detector.

The difference between composite roll and cemented carbide roll and its application characteristics

The non-destructive testing of composite rolls is usually carried out with an ultrasonic flaw detector.

What are the commonly used heat treatment types for rolls?

Commonly used heat treatment types for rolls include stress relief annealing, isothermal spheroidizing annealing, diffusion annealing, normalizing, tempering, quenching, and cryogenic treatment.